Spreading God's Love Thru Prayer

-

Labeling Machine

- Female

- Vista, CA

- United States

- Blog Posts

- Discussions

- Groups

- Photos

- Photo Albums

- Videos

RSS

Packaging Machine Design for Alcohol-Based Products: Engineering for Safety, Accuracy, and Compliance

Alcohol-based products place unique demands on packaging machinery. Unlike water-based liquids, alcohol formulations introduce challenges related to flammability, vapor management, material compatibility, and regulatory compliance. From hand sanitizers and disinfectants to spirits, extracts, and industrial alcohols, packaging lines must be engineered to handle volatility without sacrificing throughput, accuracy, or operator safety.

For California manufacturers operating under strict safety and workplace regulations, packaging machine design is not just a performance decision—it is a compliance requirement.

This article explains how packaging machinery must be engineered for alcohol-based products and highlights Accutek Packaging Equipment Company, Inc. solutions that are purpose-built for these demanding applications.

Why Alcohol-Based Products Require Specialized Packaging Machinery

Alcohol behaves differently than most liquid products on a packaging line. Its low viscosity, high evaporation rate, and flammability amplify risks that standard machines are not designed to manage.

Key engineering challenges include:

- Flammable vapor generation during filling

- Static electricity buildup

- Seal degradation from solvent exposure

- Foaming during high-speed filling

- Strict OSHA, NFPA, and local safety requirements

Packaging machinery for alcohol-based products must therefore integrate mechanical precision, material science, and safety engineering into a unified system.

Filling Machine Design for Alcohol-Based Liquids

Alcohol-based products are typically low-viscosity, fast-flowing liquids, which makes volumetric control and splash prevention critical.

Engineering Requirements

- Smooth, controlled liquid flow to prevent turbulence

- Alcohol-compatible seals, gaskets, and tubing

- Enclosed or guarded fill zones to manage vapor

- Optional explosion-proof components for high-alcohol environments

Accutek Filling Machines Used for Alcohol-Based Products

Timed Flow Volumetric Fillers

Ideal for low-viscosity alcohol products such as sanitizers, disinfectants, and ethanol solutions. These systems deliver consistent fill volumes while minimizing splash and foaming.

Overflow Fillers

Commonly used for alcohol bottles where cosmetic fill level consistency is critical, such as spirits and clear consumer products.

Piston Fillers (Configured for Alcohol)

While piston fillers are often associated with thicker products, Accutek configures stainless steel piston systems with alcohol-resistant seals for controlled filling where accuracy is critical.

All Accutek fillers for alcohol applications can be built with:

- 316 stainless steel contact parts

- Alcohol-resistant elastomers

- Optional ATEX-ready or explosion-proof electrical configurations

Managing Safety and Compliance in Alcohol Packaging Lines

Alcohol packaging is governed by overlapping safety frameworks that influence machine design.

Key Standards Affecting Packaging Machinery

- OSHA flammable liquid handling requirements

- NFPA guidelines for ignition prevention

- California workplace safety and fire codes

- Electrical classification for hazardous environments

Packaging Machinery Design Considerations

- Grounding and bonding to prevent

…

The post appeared first on Accutek Packaging Machine Equipment.

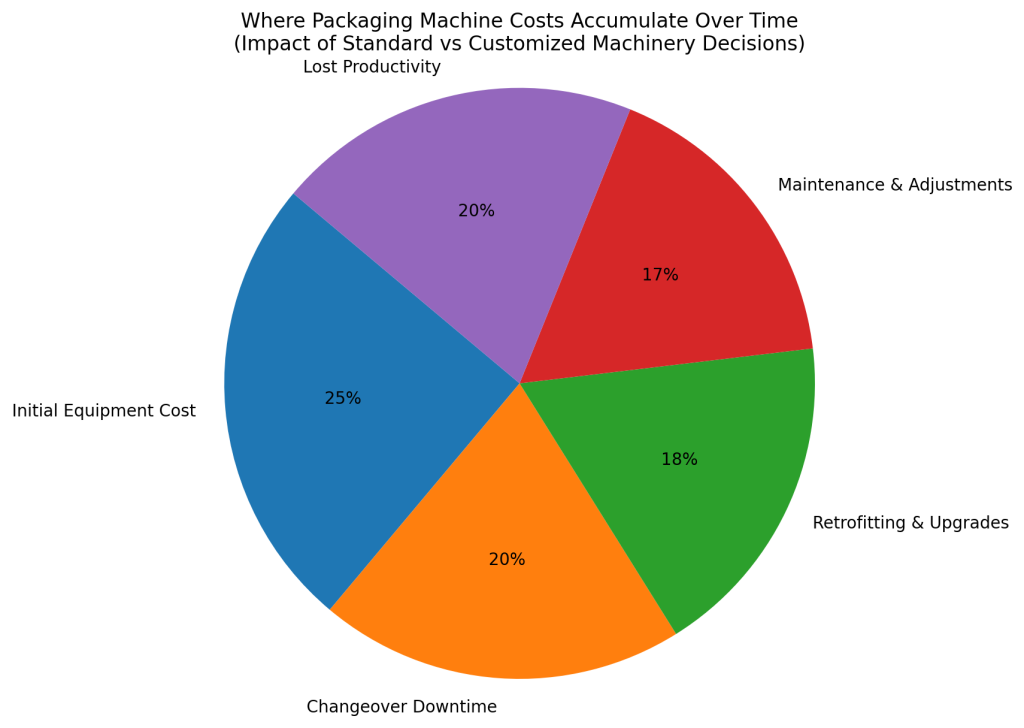

Packaging Machine Customization vs. Standard Models: What Manufacturers Must Evaluate Before Investing

Choosing the right packaging machinery is no longer just about speed or price. For growing manufacturers, the decision between a standard and a customized machinery solution can directly affect throughput, changeover efficiency, compliance, and long-term scalability.

While standard machines offer faster deployment and lower upfront costs, customization can unlock operational advantages that off-the-shelf equipment cannot deliver—especially for manufacturers dealing with multiple SKUs, unique containers, or strict regulatory requirements.

This article breaks down the real engineering, operational, and financial trade-offs between standard and customized packaging machines to help manufacturers make informed, future-proof decisions.

What Defines a Standard Packaging Machine?

It is a pre-configured system designed to accommodate common container sizes, label formats, and production speeds. These machines are built for broad market use and typically ship with fixed mechanical layouts and predefined adjustment ranges.

Where Standard Models Perform Well

- Single or limited product lines

- Stable container dimensions

- Predictable production volumes

- Faster installation timelines

It is often ideal for manufacturers entering automation for the first time or operating within narrowly defined production parameters.

What Custom Packaging Machinery Really Means

Customized packaging machinery goes beyond cosmetic changes. It involves engineering modifications that adapt the machine’s mechanics, controls, and integration points to a manufacturer’s specific production realities.

Customization may include:

- Container-specific handling components

- Adjustable or servo-driven changeover systems

- Integrated inspection, rejection, or vision modules

- Line-level synchronization with upstream and downstream equipment

Rather than forcing production to adapt to the machine, customization allows the machine to adapt to production.

Core Trade-Offs: Customization vs. Standard Models

| Evaluation Factor | Standard | Customized |

|---|---|---|

| Initial Cost | Lower upfront investment | Higher initial engineering cost |

| Deployment Speed | Faster installation | Longer lead time due to design |

| Flexibility | Limited adjustment range | Designed for SKU and format diversity |

| Changeover Efficiency | Manual or semi-manual | Engineered for fast, repeatable changeovers |

| Long-Term Scalability | Often constrained | Built to scale with production growth |

This comparison highlights a common pattern: standard machines optimize for speed to purchase, while custom machines optimize for speed to operate.

Operational Impact Over Time

Many manufacturers underestimate how packaging machinery decisions compound over years of operation.

Hidden Costs of Standard Models

- Increased downtime during format changes

- Manual adjustments leading to inconsistency

- Retrofitting expenses as production evolves

- Reduced OEE as complexity increases

Advantages of Engineered Customization

- Stable performance across product variations

- Reduced operator dependency

- Predictable maintenance schedules

- Easier line expansions without full replacement

When Standard Packaging Machinery Makes Sense

Standard packaging machines remain the right choice …

The post appeared first on Accutek Packaging Machine Equipment.

Gifts Received

Labeling Machine has not received any gifts yet

Labeling Machine's Page

Profile Information

- Relationship Status:

- Single

- About Me:

- I'm catherine martin, 29 years old and i currently working as Content Writting at ATHENA

- Are you Saved by the Blood of Jesus Christ

- yes

© 2026 Created by Guardian.

Powered by

![]()

Guardians Prayer Warriors if you would like to go to our Facebook page please click the buttons. If you would like to open up a Guardians Prayer Warriors group on a different site please contact Guardians Ministry so that we may put the name of your site on the page and you can use Guardians Prayer Warrior tags.

Guardians Prayer Warriors if you would like to go to our Facebook page please click the buttons. If you would like to open up a Guardians Prayer Warriors group on a different site please contact Guardians Ministry so that we may put the name of your site on the page and you can use Guardians Prayer Warrior tags.

Comment Wall

You need to be a member of Guardians Prayer Warriors to add comments!

Join Guardians Prayer Warriors